Summary

- Florida climate factors and how they break down coatings: UV, humidity, salt air, storms, and thermal expansion

- Interior, exterior, and commercial painting best practices, materials, and realistic repaint cycles

- Clear pricing drivers with practical examples, plus how professional prep extends lifespan

- Side-by-side coating comparisons: acrylic latex, elastomeric, urethane, epoxy, and mold-resistant formulas

Introduction

Painting in Tampa is not only about color—it’s a protective system designed to stand up to Florida’s UV exposure, high humidity, salt air, summer storms, and the constant risk of mold and mildew. The right products and preparation help prevent water intrusion, surface decay, and premature coating failure, which saves you money and protects your property value.

Professional results come from pairing the correct coating with your specific substrate and environment, then installing it with proper prep and application. If you want guidance or a turnkey team familiar with the Tampa area, Purple Painting provides climate-appropriate recommendations and reliable scheduling for homes, rentals, and commercial spaces.

Florida Climate Realities: What Your Paint Faces Daily

Florida’s environment is tough on coatings. Understanding these stressors helps you choose the right system and set realistic expectations.

- UV exposure: Intense sunlight breaks down binder resins, causing chalking, fading, and loss of gloss. Darker colors and lower-quality resins degrade faster.

- Humidity and rain: Moisture drives blistering, peeling, and mildew growth—especially on shaded sides and near landscaping. Vapor-permeable systems help walls dry out.

- Salt air: Coastal aerosol salts accelerate corrosion on metals and degrade organic binders. Frequent rinsing and high-performance primers/coatings are key near the bay and beaches.

- Thermal expansion: Daily heat cycles expand and contract stucco, wood, and metals. Flexible coatings reduce cracking and keep water out.

- Storms and wind-driven rain: Micro-cracks and weak caulking are entry points for water. Proper sealing, elastomeric bridges, and sound substrate repair are essential.

Painting Company Tampa

When you search for a painting company tampa, look for teams that specify coatings by substrate and microclimate, not just color. Ask for product data sheets, written prep steps, and a maintenance plan. A legitimate painting company tampa will discuss vapor permeability for stucco, alkyd vs. acrylic primers for wood, and how often you should wash exteriors to extend coating life.

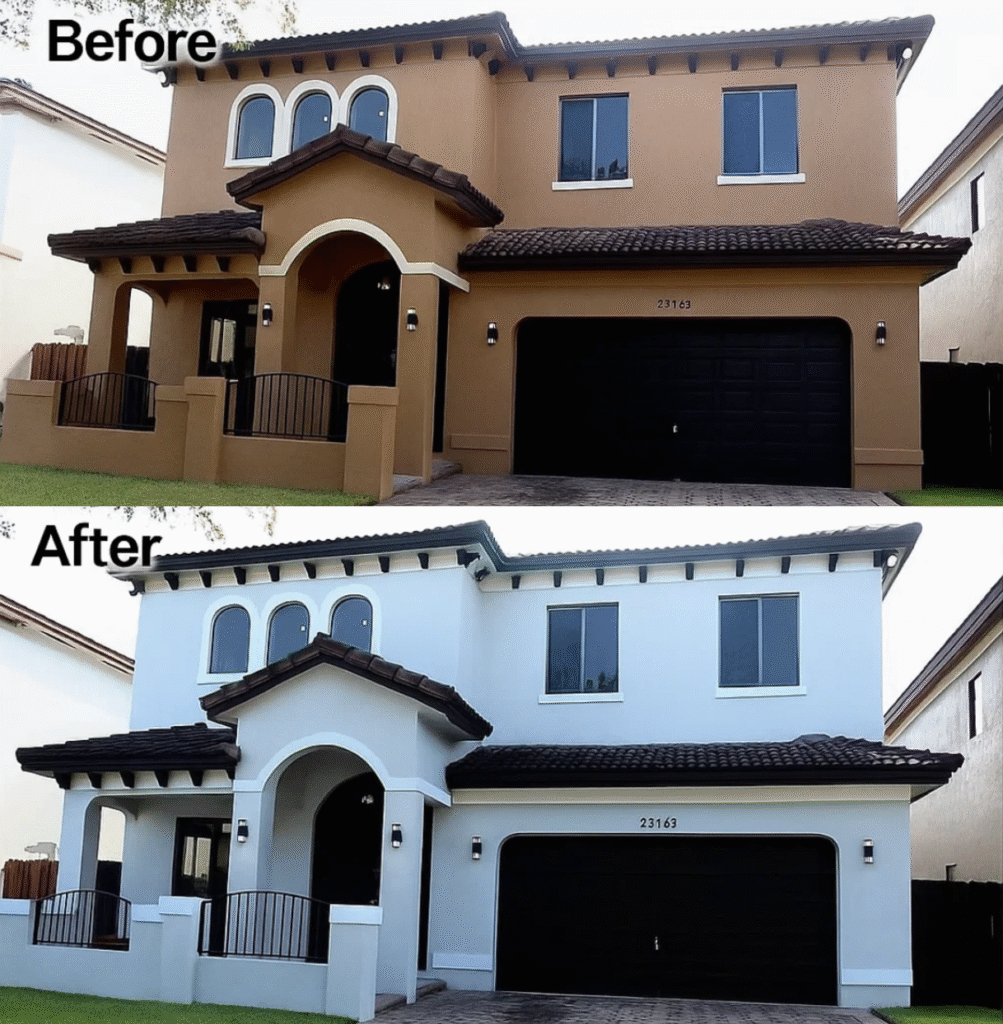

Residential Painting Value: Beyond Looks

Good paint does more than refresh color. It protects the structure and supports value.

- Protection vs. decay: Sealed stucco and properly caulked joints block water intrusion that leads to cracks, efflorescence, and interior damage.

- Resale value: Fresh, well-chosen colors make listing photos stand out and reduce buyer concerns about deferred maintenance.

- Curb appeal and HOA compliance: Many HOAs require approved palettes and routine repainting. Staying compliant avoids fines and maximizes neighborhood consistency.

- Repainting cycles: In humid zones, exterior cycles are generally shorter. Stucco needs repainting roughly every 6–8 years inland and 4–6 years in coastal zones, depending on prep, exposure, and product.

- Rental realities: Long-term rentals and short-term rentals (Airbnb) see accelerated interior wear. Choose scrubbable finishes and plan for touch-ups or partial repaints between tenants.

For more detail on property protection and ROI from proper coatings, see the 5 benefits of professional painting and maintenance for Tampa homes.

Interior Painting: Performance, Touch-Ups, and Daily Wear

Interior systems should balance color design with durability and cleanability.

- Lighting and color: Florida’s bright sun can wash out pale colors near windows while deep tones can feel heavy in small rooms. Test samples in natural and artificial light.

- Wear patterns: Pets, kids, and luggage handle walls differently. Use higher-scrub eggshell or satin in hallways, entries, and kitchens; matte or flat in low-touch ceilings and formal spaces.

- Rental turnover: Choose coatings that touch up well to reduce whole-wall repaints. Keep a documented color schedule to match future maintenance coats.

- Frequency of touch-ups: High-use areas (stairwells, baseboards, doors) may need annual touch-ups. Kitchens and baths benefit from moisture-resistant, mildew-resistant finishes.

- High-performance coatings: Zero-VOC acrylics reduce odor and downtime. Scuff-resistant formulas in satin or semi-gloss improve cleanability without a high-gloss look.

Exterior Painting: Systems Built for Florida

Exterior substrates in Tampa each require specific prep and coatings.

- Stucco: Hairline cracks need elastomeric patching or a flexible elastomeric topcoat to bridge movement. Use breathable systems that let trapped moisture escape.

- Concrete block (CMU): Use block filler where required to even porosity, then a durable 100% acrylic topcoat for UV and water resistance.

- Wood fascia and siding: Spot-prime bare wood with an oil/alkyd or bonding primer to lock tannins, then finish with quality acrylic latex for flexibility and UV resistance.

- Fiber cement or vinyl siding: Clean thoroughly to remove chalking and oxidation. Use a color within manufacturer guidance for heat absorption to avoid warping.

- Metals and railings: Rust conversion or removal, metal primers, and urethane topcoats deliver longer life in salt air.

Elastomeric coatings: These flexible, high-build systems are useful on stucco with micro-cracking. They help waterproof walls and resist wind-driven rain. Acrylic latex is still the workhorse on many exteriors due to strong UV resistance, color retention, and breathability—especially when applied over sound substrates with proper primer.

Commercial Painting: Durability and Brand Consistency

Commercial properties need coatings that stand up to traffic and frequent cleaning while presenting a professional brand image.

- First impression: Exterior color consistency and crisp trim lines influence perceived quality and cleanliness.

- High-traffic durability: Scuff- and abrasion-resistant products in lobbies, corridors, and restrooms reduce maintenance cycles.

- Healthcare and hospitality: Antimicrobial or mildew-resistant coatings support cleanliness expectations and regulatory requirements.

- Branding: Maintain color accuracy across locations. Specify formulas and sheen levels in a written standard for consistency.

- Maintenance schedules: Annual washing and targeted touch-ups extend repaint cycles. Plan off-hours work to minimize business disruption.

Paint Material Comparison: Choosing the Right System

Use the right coating in the right place. The table below compares common systems for Florida properties.

| Coating | Best Uses | Key Pros | Limitations | Florida Notes | Typical Lifespan* |

|---|---|---|---|---|---|

| 100% Acrylic Latex | Most exterior siding, stucco, interior walls/ceilings | UV resistant, breathable, color retention, easy touch-ups | Not a crack bridge; surface must be sound | Go-to for walls; pair with proper primer and caulking | 5–8 years exterior; 7–10 interior |

| Elastomeric | Stucco with hairline cracks; wind-driven rain exposure | Bridges micro-cracks, high build, water resistance | Lower vapor transmission if overused; needs sound base | Great on stucco when installed by pros; mind breathability | 6–10 years depending on exposure |

| Urethane (2K Polyurethane) | Metals, doors, railings, high-abuse trim | Excellent hardness, chemical and UV resistance | Higher cost; more complex application | Strong choice near salt air for metals | 7–12 years with maintenance |

| Epoxy Floor Systems | Garages, warehouses, kitchens, healthcare | High abrasion and chemical resistance | UV yellowing in sunlight; needs prep and topcoat | Use polyaspartic/urethane topcoat for UV zones | 5–10 years+ depending on traffic |

| Mold/Mildew-Resistant Formulas | Bathrooms, coastal exteriors, shaded elevations | Slows organic growth; easier cleaning | Not a substitute for cleaning and drainage | Valuable in humid, shaded, or coastal areas | Aligned with base coating’s lifecycle |

*Lifespans are typical ranges and depend on substrate condition, prep quality, sun/salt exposure, and maintenance.

Pros and Cons by Goal

- Max UV resistance: Acrylic latex or urethane topcoats

- Crack bridging on stucco: Elastomeric systems

- Heavy traffic floors: Epoxy with UV-stable topcoat

- Mildew resistance: Coatings with mildewcides and routine washing

Preparation Is Most of the Work

Prep quality is the top predictor of coating life. Expect most professional time to be spent before any color hits the wall.

- Washing: Pressure washing or soft washing removes dirt, chalk, and salts. Add mildewcide where growth is present. Rinse thoroughly and allow proper dry time.

- Scraping: Remove loose and flaking paint. Leave only bonded coatings.

- Sanding: Feather edges of remaining paint and de-gloss glossy areas for adhesion.

- Patching and repairs: Fill cracks and holes. On stucco, use compatible patching compounds; on wood, replace rot rather than fill it.

- Caulking and sealing: Seal joints, gaps, and penetrations with high-quality elastomeric caulk. Pay attention around windows, doors, and trim.

- Priming: Select primer by substrate and condition (stain-blocking, masonry, metal, bonding). Primers improve adhesion and uniformity.

- Masking and protection: Protect landscaping, fixtures, and surfaces with plastic and tape. Good masking saves cleanup time and prevents damage.

Skilled prep extends coating life, reduces callbacks, and helps maintain a clean, crisp finish line.

Realistic Lifespan Expectations in Tampa

These ranges assume professional prep, quality products, and routine washing. Adjust for direct waterfront exposure (more salt and wind) or heavy shade (more mildew).

| Substrate | Inland (approx.) | Coastal (approx.) | Notes |

|---|---|---|---|

| Stucco (Acrylic Latex) | 6–8 years | 4–6 years | Elastomeric may extend life on cracked stucco |

| Stucco (Elastomeric) | 8–10 years | 6–8 years | Ensure breathability strategy for moisture |

| Wood Trim/Fascia | 5–7 years | 3–5 years | Spot-prime bare wood; check caulking annually |

| CMU Block | 6–9 years | 5–7 years | Block filler improves uniformity and coverage |

| Metal Railings (Urethane) | 7–12 years | 5–9 years | Regular rinsing helps in salt air |

| Interior Walls (Premium Acrylic) | 7–10 years | 7–10 years | Touch-ups as needed; baths need mildew resistance |

| Rental/Airbnb Interiors | 3–5 years | 3–5 years | High-traffic and cleanability demand earlier refresh |

Pricing Clarity: What Drives Cost

Every property is unique. The following are drivers, not quotes.

- Substrate and condition: Worn stucco, chalking block, or peeling wood require more prep. Rot replacement or stucco repair increases cost.

- Square footage and complexity: More wall area and detailed trim increase labor and material use.

- Prep severity: Extensive scraping, priming, and caulking add time and materials.

- Coating selection: Elastomerics, urethanes, and specialty mold-resistant products cost more than standard acrylics.

- Access and height: Lifts, scaffolding, or complex rooflines add setup time and equipment costs.

- Number of coats and colors: Deep colors, drastic color changes, and brand-accurate multi-color schemes may require extra coats.

- Scheduling: Night or off-hour work for commercial spaces and staged projects for occupied homes can affect labor rates.

Practical Examples (Not Quotes)

- Interior repaint, occupied 3-bed home, walls and trim only: Time and cost vary with wall condition, furniture moving, and whether ceilings or closets are included. Washable, low-odor paints may cost more but reduce disruption.

- Exterior stucco home, inland, moderate prep: Cost changes with crack repairs, window caulking, and whether an elastomeric system is chosen for added protection.

- Commercial office corridor refresh: Scuff-resistant acrylic eggshell or urethane-reinforced products add upfront cost but can cut repaints over a 5–7 year cycle.

Request a site assessment to match scope, materials, and timeline to your property’s needs.

Curb Appeal and Property Value

- Listing photos: Fresh exteriors pop in online searches. Crisp trim and updated front doors make a strong first impression.

- Buyer expectations: Clean, neutral interiors suggest a well-maintained home. Buyers notice paint lines, door edges, and caulk quality.

- Appraisal perception: While paint does not change square footage, it can influence condition ratings and reduce repair allowances requested by buyers.

- Rental demand: Bright, clean, durable finishes reduce vacancy time and help attract quality tenants or guests.

Color Selection Fundamentals for Florida

- Heat absorption: Dark colors absorb more heat and may fade faster in direct sun. Light to mid-tones typically perform better outdoors.

- Neutral strategy: Use timeless neutrals for large areas and bolder accents for doors or specific feature walls. This approach eases future updates.

- HOA compliance: Confirm approved exterior palettes before purchasing paint. Obtain written approvals if required.

- Commercial branding: Standardize color codes (brand PMS, RAL, or manufacturer-specific IDs) and sheens across locations to maintain consistency.

DIY Drawbacks in Florida’s Climate

- Improper primer selection: Wrong primer leads to tannin bleed on wood or poor adhesion on masonry and glossy surfaces.

- Humidity reactivity: Applying paint outside recommended temperature or humidity ranges causes flashing, sags, or extended cure times.

- Mold and mildew: Painting over growth traps problems beneath the film. Proper washing and mildewcides are necessary.

- Poor adhesion: Skipping de-glossing or sanding risks peeling, especially on doors and trim.

- Safety hazards: Ladders, roofs, and lifts require training and protective gear.

- Wasted time and materials: Rework and premature failure often cost more than hiring a pro from the start.

Professional Criteria: How to Choose

- Licensing and insurance: Verify active state or local licensing where applicable and proof of liability and workers’ compensation coverage.

- Written scope and warranty: Look for detailed prep steps, primer and product specs, coat counts, and a clear labor/materials warranty.

- Crew size and supervision: Ask who will be on-site, daily start/stop times, and how progress and cleanup are managed.

- Coating selection: Expect substrate-specific recommendations and data sheets for key products.

- Scheduling and communication: For homes and businesses, a clear schedule and point of contact reduce disruption.

- References and photos: Ask for recent, similar Florida projects—especially near your microclimate (coastal vs. inland).

FAQs

How often should a Tampa home be repainted?

Exteriors typically every 4–8 years depending on exposure and product. Interiors last 7–10 years, but high-traffic areas may need touch-ups sooner.

Does stucco require primer?

Often yes. New or chalky stucco benefits from masonry primer or block filler. For repaints, test for chalking; prime as needed for adhesion and uniformity.

Which paint lasts longest in salt air?

High-quality 100% acrylic latex for walls and urethane topcoats for metals perform well. Regular rinsing and maintenance extend life.

What prep is necessary before exterior painting?

Wash, remove mildew, scrape, sand, repair, caulk, and spot-prime or fully prime as required. Quality prep is the main factor in coating longevity.

Is elastomeric beneficial for stucco?

Yes for hairline cracks and wind-driven rain. Ensure the system remains breathable and the substrate is sound.

Why do interior walls scuff so easily?

Low-sheen or low-quality paint can scuff, especially in high-traffic areas. Use premium, scuff-resistant acrylics and the right sheen.

How do commercial coatings differ from residential?

Commercial systems emphasize abrasion, chemical resistance, and cleanability, often with higher-performance resins and stricter prep standards.

Can I repaint over mildew?

No. Clean and treat mildew first; then prime and paint. Painting over growth leads to early failure.

Working With a Local Pro

Hiring locally means your team understands Tampa’s humidity, seasonal weather windows, and HOA and commercial scheduling requirements. Expect advice tailored to your elevation exposures, shade patterns, and proximity to salt air.

Conclusion

Florida’s climate demands the right system, not just the right color. When you pair thorough prep with climate-appropriate coatings, you get longer-lasting exteriors, cleaner interiors, better curb appeal, and lower lifetime costs. If you want a local team that prioritizes durability, scheduling, and clear communication, request a consultation from Purple Painting to plan your next interior, exterior, or commercial project.